Perfection is The Enemy

I guarantee no matter how long you’ve been doing that thing, you will still make mistakes and you’ll have to overcome them. But that’s not what this is about. It’s about perfection. The enemy of us all.

One common misconception in woodworking is everything has to be perfect. I know I look at a factory made table and I see all the flaws and imperfections which I know I can improve upon if I make my own. Then I make my own and I realize how hard it is to make something perfect. I spend twice as long as I should because I worry about small details, spending hours fine tuning with chisels and sand paper to achieve a perfect joint that no one will ever see.

Is the final piece an improvement over the factory table? Sure, but not because of those hidden details. It’s an improvement because I made it. I poured my time and energy into building something I will use every day that will last a lifetime. Is the top perfectly flat? No. Is there a flaw in one of the glue joints where I had a little tear out and it showed up after sanding? Yes. And that is all okay because handmade cannot be factory perfect, but that doesn’t make it imperfect. You made it, so it’s perfect. And, in 5 years after you have new skills and better tools you can go back and build a new one even better than the last.

My Calvert Square End Table, it has some flaws most people won’t even notice unless I point them out.

For example, if you look in the middle of the table, the right black section has some minor tear out due to the figure in the wood. I knew it and left it because that is a highlight area of the entire piece.

One thing I want to stress is, don’t stop building because you are afraid to make mistakes.

I was recently talking to Kris, a fellow woodworker. I had posted a video about painting, you can watch and read more about my painting technique here, and I received comments from painters about better ways to paint for better results. I agreed with those folks but also said I knew this wouldn’t be perfect, I’m not setup with a spray booth and all the equipment to paint, but I had a job to get done and did my best. Kris told me at one point he was so scared of making mistakes that he completely gave up on making things, but mistakes are inevitable, they will happen regardless of your efforts to avoid them. He said to me that “the mark of a good craftsman is how elegantly you are able to resolve the problem.” I love that. We as humans make mistakes and we as craftsmen fix those mistakes.

About Plans

When I was a beginner woodworker I used to agonize over cuts. I wanted them to be perfect. I would measure, mark my piece, and cut exactly on my line only to realize I marked an inch off and now have a board that is too short.

Then I would stop the project for months because I didn’t want to buy more material because my piece wouldn’t be the planned size. Not only was I stopping my progress on the project, I was delaying the lesson I was in the middle of learning so I could improve and be better next time. And for what, to make a stand alone piece of furniture exactly to meet a plan instead of sizing it slightly smaller to meet my material? If this was going to fit perfectly between two walls then maybe I’d worry about that one inch, but if it’s standalone no one will know.

While we’re talking about plans, let me start by saying plans are great. They help us understand the size of the final piece and plan out all our parts. Furniture can be deceptively complex to get everything fit together right. But plans can also be a trap. There are times I don’t follow my own plans. Yes I’ll make a frame with the dimensions I want, but if I’m off of the plan slightly, I will adjust.

I may draw up plans with 24 and 3/16” long table legs. In reality, the length of those legs is arbitrary. They need to be somewhere in the ballpark otherwise the table will be too short, but more importantly than the measurement of each length is to have each leg the exact same length to keep the table from wobbling. Whether that’s 24 5/32” or even 23”, it doesn’t matter as long as the table works for your space.

And that’s the key, it needs to work. You can’t make a desk that sits 6 inches off the ground and expect to use it with a desk chair. You can make the desk a slightly different size than specification to have it still be a fully functional desk.

Cut to Fit

Next time you have a project try my cut to fit technique, for further detail visit my blog on the subject. For a short version, we’ll use the example of building a simple storage crate.

Start by figuring out how big you want that crate. Get your wood and mark how long one side needs to be. Now cut it to the outside of that mark, leaving the piece just slightly long.

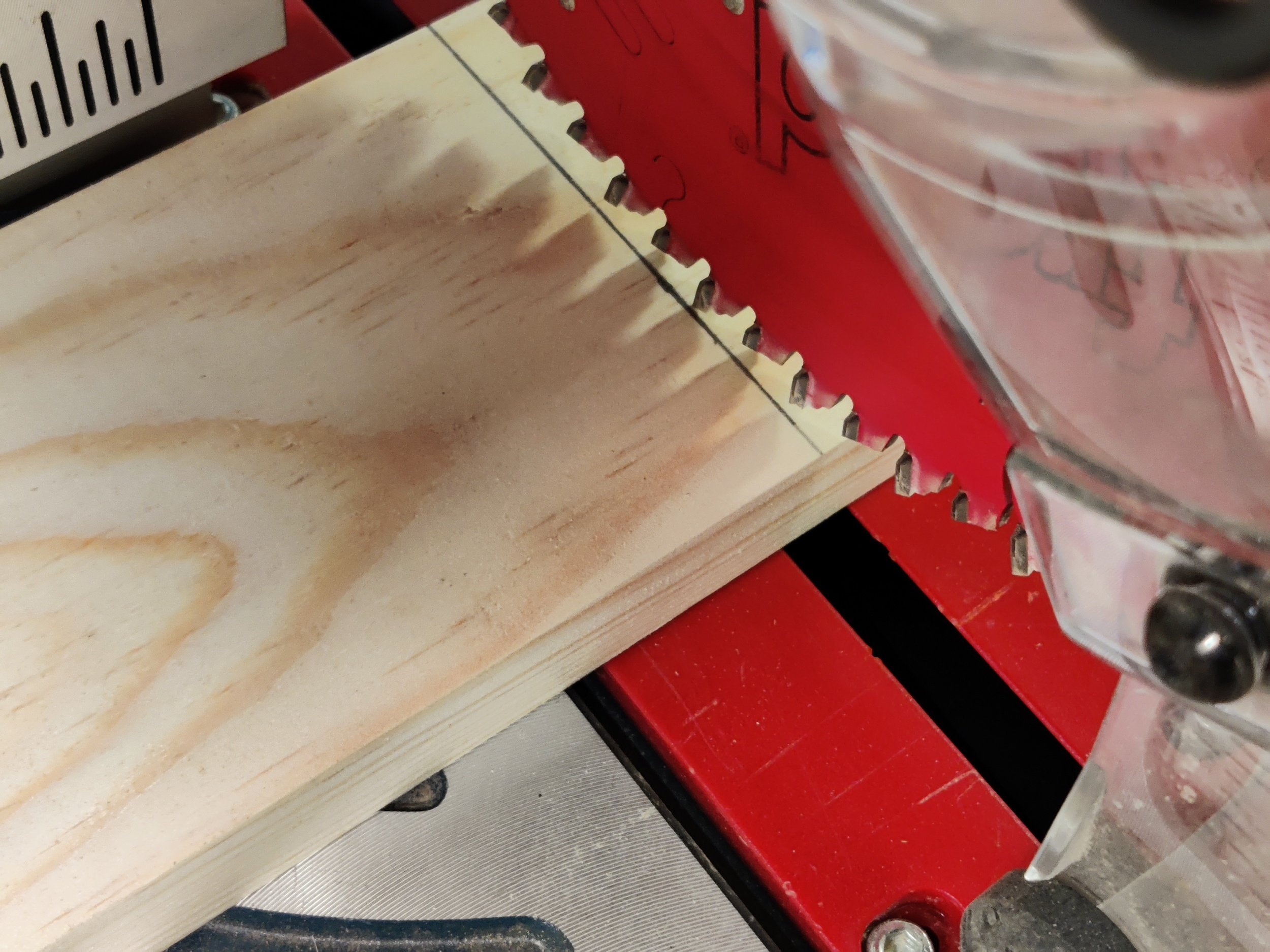

Leaving a pencil line often gives me just enough wiggle room to fine tune my fit later. Also, make sure you pay attention to the offset on your teeth when lining up the saw. On this blade, every other tooth’s point is on the left side. You want to line up your saw to your mark with, in this case, the left leaning tooth. If you line it up with the tooth angled to the right you will be guessing at how close you are instead of seeing the tooth touch your line. Remember, you can always cut more off, but you can’t add it back, so leave yourself some room if you think you need it.

Next, lay that cut board on top of the remaining portion of your board. Line up the ends so they are flush and cut again, making sure to skim off a slight amount on the cut board. Now you have two identical sides. Repeat for the other two sides and you’ll have a perfectly square box (the box may not be a square in the geometric sense of the word, but each corner will be 90 degrees) and you didn’t have to chase perfect measurements and cuts on every single board.

Like magic you can make a box. Will it be perfect? No. Does it need to be? No.

It’s the same principle I use when making picture frames. Perfect miters are easy as long as each parallel side of the frame is exactly the same length. Even if your miter angles are slightly off, if done right, you’ll have nice, tight miters which is what counts.

Keep Improving

When it comes to wood working, you will be your own worst critic. You will know where every flaw is because of your attention to detail and it is important for you to know so you can improve later, but remember, don’t worry about the small things and definitely don’t let them stop you from moving forward. You are doing something most people will never do. You are making something out of wood with your own hands. You should be proud of yourself and your work. It’s okay to have an imperfect project because you are learning and your next project will be even better than your last.

It doesn’t matter what the plans say. Cut to fit, move on, and enjoy your work.